How to Choose a Packaging Machine for Small Production

A Practical Guide for Entrepreneurs

Introduction: Why This Choice Is Critical

One of the most common and costly mistakes when starting a small production is the wrong choice of packaging equipment.

Some entrepreneurs buy overly expensive equipment that cannot justify the real workload. Others buy too weak equipment, which causes production to be delayed for several months.

In practice, we often encounter such a picture: the product is good, there is demand in the market, but the packaging cannot keep up with the pace of production or does not meet visual and technical requirements.

In this article, we will explain step by step how to choose a packaging machine for small production so that it really suits your needs today and tomorrow.

1. Determine the type of product (the basis for everything)

Choosing a packaging machine always starts with one question:

What am I packaging?

The type of product determines the design, dosing method and packaging material of the machine.

Main categories:

Liquid products – oil, sauce, beverage

Powder – flour, cocoa, spices

Granulated / granular – sugar, coffee, nuts

Solid products – beans, sweets, details

Bottles / containers – with labeling or shrink-wrap

📌 The same machine cannot serve all types of products with quality.

2. Main types of packaging machines

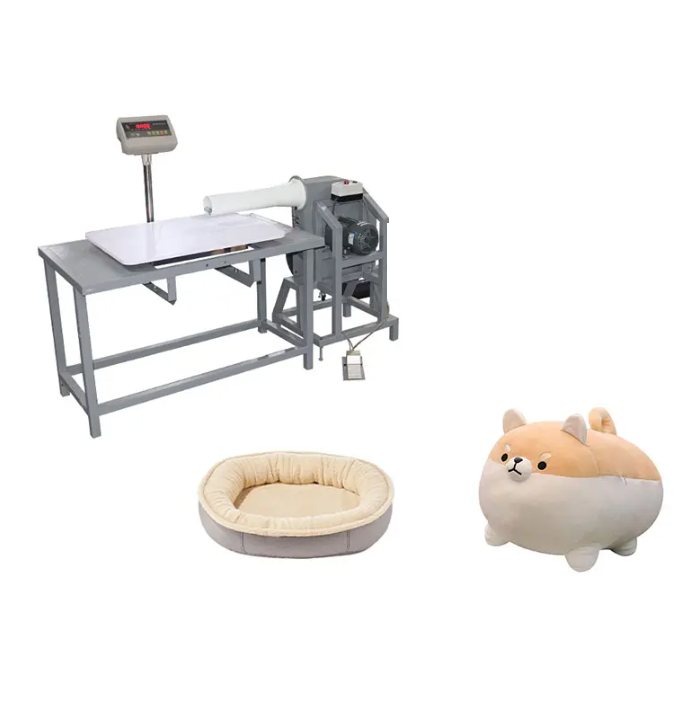

2.1 Filling and sealing machines (Filling & Sealing)

Used for dosing the product and hermetically closing the package.

Suitable for both liquid, powder and granular products.

When is it best:

If you need accurate dosing and easy operation in small batches.

2.2 Vertical Form-Fill-Seal (VFFS)

The machine automatically creates a package from the film, fills it and seals it.

Suitable for:

Coffee

Snacks

Powder

Cereals

✔ Compact

✔ Popular in small production

✔ Good price/performance ratio

2.3 Horizontal packaging (Flow pack / HFFS)

The product is wrapped horizontally with film.

Ideal for:

Long or fixed-shaped products

Sweets

Individual units

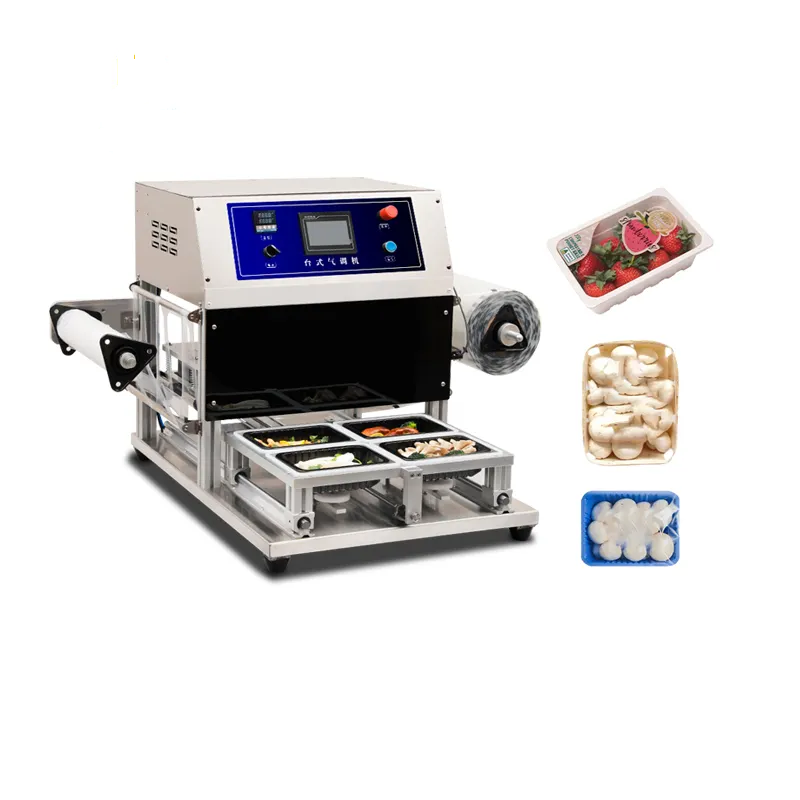

2.4 Vacuum packaging machines

Vacuum increases the shelf life of the product and protects it from air.

Commonly used in:

Meat products

Cheese

Ready-to-eat food

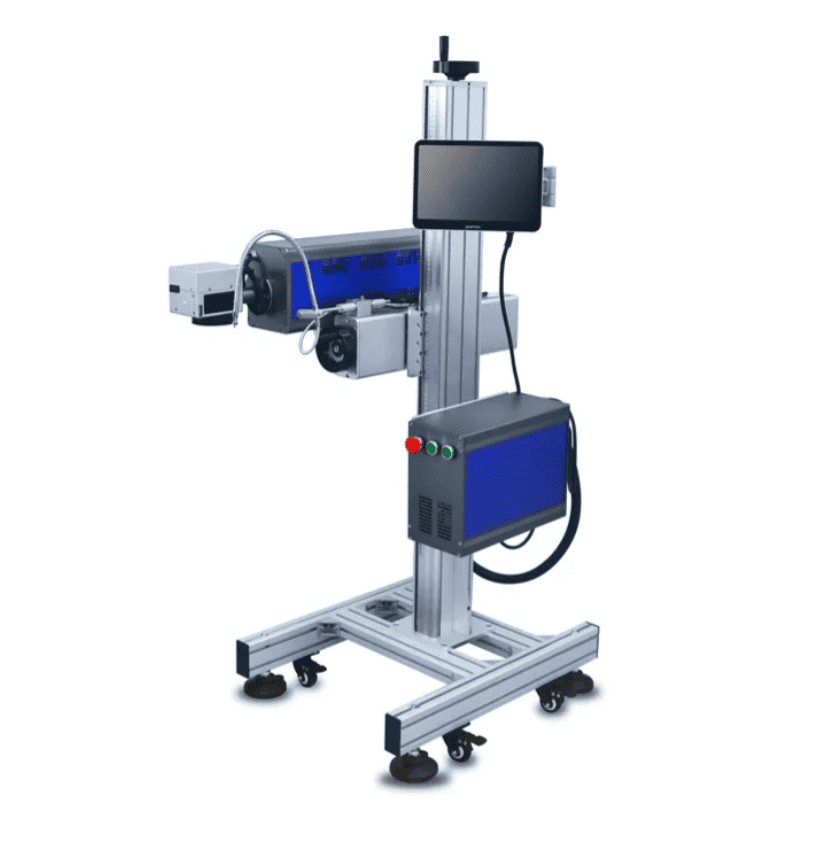

2.5 Shrink tunnel / thermo-shrink systems

Used to shrink wrap around bottles, cans or boxes.

Additional benefits:

Better visual appearance

Transport protection

Professional look

3. Automation level: How big should the machine be?

Small start-up

Semi-automatic machines

Low investment

Easy to train

Recommended if production does not exceed 100–500 units per day.

Growing small businesses

Automatic or combined systems

Less manual labor

Consistent quality

Best price/performance ratio.

High volume

Fully automated lines

Conveyors

Need for technical support

📌 It is often a mistake to move to such a stage too early.

4. 5 main factors that you must definitely consider

1️⃣ Production volume

How many units do you need per day and hour?

2️⃣ Packaging material

PVC

PP

PE

POF

Paper / biodegradable film

The machine must be adapted to the specific material.

3️⃣ Ease of operation

In small production, the following are important:

Easy operation

Quick cleaning

Fewer repairs

4️⃣ Service and spare parts

In practice, this is often where problems arise.

A cheap machine that is not serviced will end up costing you a lot.

5️⃣ Future growth

Ask yourself:

Will I use this machine again in 1–2 years?

5. The most common mistakes in small production

Choosing only by price

Overestimating productivity

Incompatibility with packaging materials

Ignoring service

Not calculating future expansion

📌 These mistakes are the most common in practice and the most expensive.

Conclusion

The right packaging machine is not just a piece of equipment —

It is the basis of stable production, quality products and quiet operation.

If you make a choice:

By product type

By calculating real volumes

Taking into account service and future growth

Then the machine will work for you, and not you — for it.

Frequently Asked Questions (FAQ)

Which packaging machine is best for small production?

It depends on the type of product, daily volume and budget. The most commonly used are semi-automatic and VFFS systems.

Is it better to have a cheap or expensive machine?

It is better to have one that has service and corresponds to your real workload.

Is it possible to package different products on one machine?

In some cases – yes, but it depends on the dosing and film system

Author: Badri Tsikubadze – entrepreneur working in the field of technological equipment and packaging machinery.